Technology with Extrusion of Plastics: Design Quality

Wiki Article

Plastic Extrusions: Enhancing Performance as well as Performance With Plastic Extrusions

Are you seeking to enhance performance and also efficiency in your market? Look no more than plastic extrusions. With their many benefits as well as vital aspects influencing efficiency, plastic extrusions are the service you require.In this article, we will discover strategies for optimizing effectiveness as well as technologies that can take your procedures to the next degree. Prepare yourself to discover real-life study showcasing the effective implementation of plastic extrusions.

Don't miss out on out on this chance to change your company.

Perks of Plastic Extrusions in Enhancing Efficiency

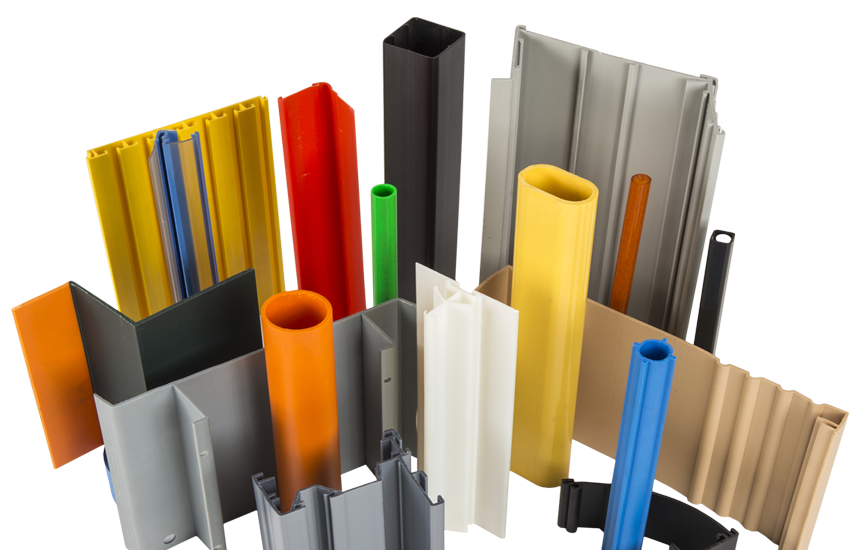

You can substantially boost your performance with plastic extrusions. These flexible parts offer many advantages that can improve effectiveness in different markets.Plastic extrusions are lightweight, making them simple to take care of and mount. Whether you are in the building and construction, automotive, or product packaging market, this attribute enables quick as well as hassle-free setting up, saving you beneficial time as well as initiative.

Furthermore, plastic extrusions are extremely customizable, allowing you to tailor them to your particular demands. With the capability to produce detailed sizes and shapes, you can enhance your processes and also take full advantage of performance.

Additionally, plastic extrusions are recognized for their toughness as well as resistance to damage. This means that when installed, they need marginal upkeep, decreasing downtime as well as enhancing your total operational effectiveness.

Plastic extrusions use exceptional thermal and also electrical insulation homes, making them appropriate for a wide variety of applications. From cord administration to weatherproofing, these elements can help enhance your procedures and also improve efficiency.

Secret Factors Affecting Performance in Plastic Extrusions

One of the key aspects that affect efficiency in plastic extrusions is the proper option of materials. When it pertains to plastic extrusions, selecting the ideal materials is vital for accomplishing optimum performance as well as effectiveness. The kind of material utilized can substantially influence the extrusion procedure, as well as the top quality as well as longevity of the last item.By choosing materials that have the best homes and characteristics, you can make sure that the extrusion procedure runs efficiently and also effectively. Making use of products with good warm resistance can avoid melting or contortion during the extrusion procedure. Products with high toughness and also toughness can result in a last item that is solid as well as long-lasting.

One more essential variable to consider is the compatibility of the materials with the extrusion devices. Various products may call for different processing specifications, such as temperature level and rate, to achieve ideal outcomes. Selecting materials that are fit to the details extrusion equipment being utilized can aid stop concerns such as clogging, irregular circulation, or inadequate item top quality.

In addition to material choice, various other elements such as die layout, handling problems, and operator knowledge additionally play a role in the performance of plastic extrusions. By beginning with the correct choice of products, you can set a strong structure for accomplishing high-grade and also efficient extrusions.

Techniques for Enhancing Effectiveness in Plastic Extrusions

To optimize performance in plastic extrusions, it is very important to thoroughly take into consideration elements such as die layout, handling problems, as well as driver experience. By focusing on these crucial locations, you can dramatically enhance the efficiency as well as performance of your extrusion process.Allow's talk concerning pass away style. The style of the die plays a vital role in identifying the high quality and consistency of the extruded plastic. It's important to guarantee that the die is appropriately developed, with the ideal dimensions and also shape, to attain the preferred item specs. Additionally, taking into consideration elements such as land length, land clearance, as well as departure angle can aid in lowering waste as well as improving the total efficiency of the extrusion procedure.

Speed, pressure, and also temperature are vital variables that affect the extrusion process. It's vital to monitor and also adjust these problems to enhance the efficiency as well as efficiency of the extrusion procedure.

Driver competence plays a substantial role in taking full advantage of efficiency. Well-trained operators can identify and fix problems promptly, making sure smooth operation and minimal downtime. Offering appropriate training as well as ongoing support to your operators can enhance their abilities and expertise, leading to boosted performance as well see as efficiency.

Developments in Plastic Extrusions for Boosted Performance

Remaining upgraded on the latest technologies is crucial when it comes to enhancing the performance of your plastic extrusion procedure. Innovation is regularly progressing, and also new developments in plastic extrusions can help improve the efficiency as well as efficiency of your procedures.One of the most recent advancements in plastic extrusions is the use of advanced air conditioning systems. These systems make sure that the extruded plastic is rapidly cooled down and solidified, resulting in greater manufacturing speeds as well as enhanced product high quality. By including these cooling systems right into your procedure, you can minimize cycle times and raise performance.

By fine-tuning these criteria, you can maximize the extrusion process and achieve accurate and regular results. This not just boosts product high quality but additionally minimizes waste as well as lessens downtime.

Developments in material formulas have actually led to the development of new high-performance plastics. These plastics supply enhanced toughness, resilience, and also warmth resistance, making them suitable for a vast array of applications - extrusion of plastics. By utilizing these ingenious products, you can improve the performance and capability of your products

Situation Research Studies: Successful Application of Plastic Extrusions for Effectiveness and Efficiency

Taking a look at effective study can offer beneficial understandings on how executing plastic extrusions has improved efficiency as well as performance in different sectors.One such instance study comes from the automobile sector. Making use of plastic extrusions in the production process has considerably minimized production time as well as enhanced total efficiency. By changing standard steel parts with plastic extrusions, manufacturers streamlined their procedures as well as accomplished expense savings.

Plastic extrusions have been made use of to improve the performance of windows and also doors. By utilizing plastic extrusions rather of conventional products like timber or metal, producers developed products that are extra sturdy, weather-resistant, as well as energy-efficient.

In the product packaging industry, plastic extrusions have changed exactly how items are packaged and shielded during transport. Custom-made plastic extrusions have enabled manufacturers to go to my site produce light-weight packaging services that offer superior protection versus damage. This has reduced the danger of product damages during transit and also reduced delivery expenses for business.

Final thought

There you have it âEUR" plastic extrusions are a game-changer when it comes to enhancing effectiveness as well as efficiency.By enhancing essential elements and also implementing innovative methods, organizations can greatly enhance their operations. Whether it's decreasing waste, enhancing efficiency, or accomplishing expense financial savings, plastic extrusions offer an option.

Do not simply take our word for it, there are many successful instance research studies that prove the efficiency of plastic extrusions.

So why wait? Start discovering the advantages of plastic extrusions today and also take your effectiveness as well as performance to new heights. extrusion of plastics.

With their various advantages and also essential aspects impacting performance, plastic extrusions are the remedy you require.

One of the essential aspects that affect efficiency in plastic extrusions is the check correct option of materials. When it comes to plastic extrusions, picking the appropriate materials is crucial for achieving optimum performance and effectiveness. The use of plastic extrusions in the production procedure has actually substantially minimized manufacturing time and boosted total performance. Plastic extrusions have actually been utilized to boost the performance of windows as well as doors.

Report this wiki page